| [1] |

Liu Z, Wang K, Chen Y, et al. Third-generation biorefineries as the means to produce fuels and chemicals from CO 2. Nat Catal, 2020, 3(3): 274-288. DOI:10.1038/s41929-019-0421-5

|

|

| [2] |

Jia DC, He MY, Tian Y, et al. Metabolic engineering of gas-fermenting Clostridium ljungdahlii for efficient co-production of isopropanol, 3-hydroxybutyrate, and ethanol. ACS Synth Biol, 2021, 10(10): 2628-2638. DOI:10.1021/acssynbio.1c00235

|

|

| [3] |

Liew FE, Nogle R, Abdalla T, et al. Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale. Nat Biotech, 2022, 40(3): 335-344. DOI:10.1038/s41587-021-01195-w

|

|

| [4] |

Liu C, Colón BC, Ziesack M, et al. Water splitting-biosynthetic system with CO 2 reduction efficiencies exceeding photosynthesis. Science, 2016, 352(6290): 1210-1213. DOI:10.1126/science.aaf5039

|

|

| [5] |

Su Y, Cestellos-Blanco S, Kim JM, et al. Close-packed nanowire-bacteria hybrids for efficient solar-driven CO 2 fixation. Joule, 2020, 4(4): 800-811. DOI:10.1016/j.joule.2020.03.001

|

|

| [6] |

Zhang S, Liu X, Luo H, et al. Morphological modulation of Co 2C by surface-adsorbed species for highly effective low-temperature CO 2 reduction. ACS Catal, 2022, 12(14): 8544-8557. DOI:10.1021/acscatal.2c02020

|

|

| [7] |

Su X, Jiang Z, Zhou J, et al. Complementary operando spectroscopy identification of in-situ generated metastable charge-asymmetry Cu 2-CuN 3 clusters for CO 2 reduction to ethanol. Nat Commun, 2022, 13(1): 1322. DOI:10.1038/s41467-022-29035-8

|

|

| [8] |

Bai X, Chen W, Zhao C, et al. Exclusive formation of formic acid from CO 2 electroreduction by a tunable Pd-Sn alloy. Angew Chem Int Ed Engl, 2017, 56(40): 12219-12223. DOI:10.1002/anie.201707098

|

|

| [9] |

Song Y, Chen W, Zhao C, et al. Metal-free nitrogen-doped mesoporous carbon for electroreduction of CO 2 to ethanol. Angew Chem Int Ed Engl, 2017, 56(36): 10840-10844. DOI:10.1002/anie.201706777

|

|

| [10] |

Gao P, Li S, Bu X, et al. Direct conversion of CO 2 into liquid fuels with high selectivity over a bifunctional catalyst. Nat Chem, 2017, 9(10): 1019-1024. DOI:10.1038/nchem.2794

|

|

| [11] |

Wang J, Li G, Li Z, et al. A highly selective and stable ZnO-ZrO 2 solid solution catalyst for CO 2 hydrogenation to methanol. Sci Adv, 2017, 3(10): e1701290. DOI:10.1126/sciadv.1701290

|

|

| [12] |

Ma W, Xie S, Zhang XG, et al. Promoting electrocatalytic CO 2 reduction to formate via sulfur-boosting water activation on indium surfaces. Nat Commun, 2019, 10(1): 892. DOI:10.1038/s41467-019-08805-x

|

|

| [13] |

Cai T, Sun H, Qiao J, et al. Cell-free chemoenzymatic starch synthesis from carbon dioxide. Science, 2021, 373(6562): 1523-1527. DOI:10.1126/science.abh4049

|

|

| [14] |

Sheng X, Himo F. Mechanisms of metal-dependent non-redox decarboxylases from quantum chemical calculations. Comput Struct Biotechnol J, 2021, 19: 3176-3186. DOI:10.1016/j.csbj.2021.05.044

|

|

| [15] |

Sheng X, Patskovsky Y, Vladimirova A, et al. Mechanism and structure of γ-resorcylate decarboxylase. Biochem, 2018, 57(22): 3167-3175. DOI:10.1021/acs.biochem.7b01213

|

|

| [16] |

Sheng X, Zhu W, Huddleston J, et al. A combined experimental-theoretical study of the LigW-catalyzed decarboxylation of 5-carboxyvanillate in the metabolic pathway for lignin degradation. ACS Catal, 2017, 7(8): 4968-4974. DOI:10.1021/acscatal.7b01166

|

|

| [17] |

Martin J, Eisoldt L, Skerra A. Fixation of gaseous CO 2 by reversing a decarboxylase for the biocatalytic synthesis of the essential amino acid l-methionine. Nat Catal, 2018, 1(7): 555-561. DOI:10.1038/s41929-018-0107-4

|

|

| [18] |

Aleku GA, Roberts GW, Titchiner GR, et al. Synthetic enzyme-catalyzed CO 2 fixation reactions. ChemSusChem, 2021, 14(8): 1781-1804. DOI:10.1002/cssc.202100159

|

|

| [19] |

Sheng X, Lind ME, Himo F. Theoretical study of the reaction mechanism of phenolic acid decarboxylase. FEBS J, 2015, 282(24): 4703-13. DOI:10.1111/febs.13525

|

|

| [20] |

Bernhardsgrütter I, Stoffel GMM, Miller TE, et al. CO 2-converting enzymes for sustainable biotechnology: from mechanisms to application. Curr Opin in Biotech, 2021, 67: 80-87. DOI:10.1016/j.copbio.2021.01.003

|

|

| [21] |

Glueck SM, Gümüs S, Fabian WM, et al. Biocatalytic carboxylation. Chem Soc Rev, 2010, 39(1): 313-28. DOI:10.1039/B807875K

|

|

| [22] |

Scheffen M, Marchal DG, Beneyton T, et al. A new-to-nature carboxylation module to improve natural and synthetic CO 2 fixation. Nat Catal, 2021, 4(2): 105-115. DOI:10.1038/s41929-020-00557-y

|

|

| [23] |

Payer SE, Faber K, Glueck SM. Non-oxidative enzymatic (de) carboxylation of (hetero) aromatics and acrylic acid derivatives. Adv Synth Catal, 2019, 361(11): 2402-2420. DOI:10.1002/adsc.201900275

|

|

| [24] |

Zhang X, Ren J, Yao P, et al. Biochemical characterization and substrate profiling of a reversible 2, 3-dihydroxybenzoic acid decarboxylase for biocatalytic Kolbe-Schmitt reaction. Enzyme Microb Technol, 2018, 113: 37-43. DOI:10.1016/j.enzmictec.2018.02.008

|

|

| [25] |

Song M, Zhang X, Liu W, et al. 2, 3-dihydroxybenzoic acid decarboxylase from Fusarium oxysporum: crystal structures and substrate recognition mechanism. Chembiochem, 2020, 21(20): 2950-2956. DOI:10.1002/cbic.202000244

|

|

| [26] |

Ren J, Yao P, Yu S, et al. An unprecedented effective enzymatic carboxylation of phenols. ACS Catal, 2016, 6(2): 564-567. DOI:10.1021/acscatal.5b02529

|

|

| [27] |

Ma S, Ludwig R. Direct electron transfer of enzymes facilitated by cytochromes. ChemElectroChem, 2019, 6(4): 958-975. DOI:10.1002/celc.201801256

|

|

| [28] |

Tasca F, Gorton L, Harreither W, et al. Comparison of direct and mediated electron transfer for cellobiose dehydrogenase from phanerochaete sordida. Anal Chem, 2009, 81(7): 2791-2798. DOI:10.1021/ac900225z

|

|

| [29] |

Algov I, Alfonta L. Use of protein engineering to elucidate electron transfer pathways between proteins and electrodes. ACS Meas Sci Au, 2022, 2(2): 78-90. DOI:10.1021/acsmeasuresciau.1c00038

|

|

| [30] |

Song H, Ma C, Liu P, et al. A hybrid CO2 electroreduction system mediated by enzyme-cofactor conjugates coupled with Cu nanoparticle-catalyzed cofactor regeneration. J CO 2 Util, 2019, 34: 568-575. DOI:10.1016/j.jcou.2019.08.007

|

|

| [31] |

Liu X, Kang F, Hu C, et al. A genetically encoded photosensitizer protein facilitates the rational design of a miniature photocatalytic CO 2-reducing enzyme. Nat Chem, 2018, 10(12): 1201-1206. DOI:10.1038/s41557-018-0150-4

|

|

| [32] |

Kang F, Yu L, Xia Y, et al. Rational design of a miniature photocatalytic CO 2-reducing enzyme. ACS Catal, 2021, 11(9): 5628-5635. DOI:10.1021/acscatal.1c00287

|

|

| [33] |

Siegel JB, Smith AL, Poust S, et al. Computational protein design enables a novel one-carbon assimilation pathway. PNAS, 2015, 112(12): 3704-9. DOI:10.1073/pnas.1500545112

|

|

| [34] |

Hu G, Li Z, Ma D, et al. Light-driven CO 2 sequestration in Escherichia coli to achieve theoretical yield of chemicals. Nature Catalysis, 2021, 4(5): 395-406. DOI:10.1038/s41929-021-00606-0

|

|

| [35] |

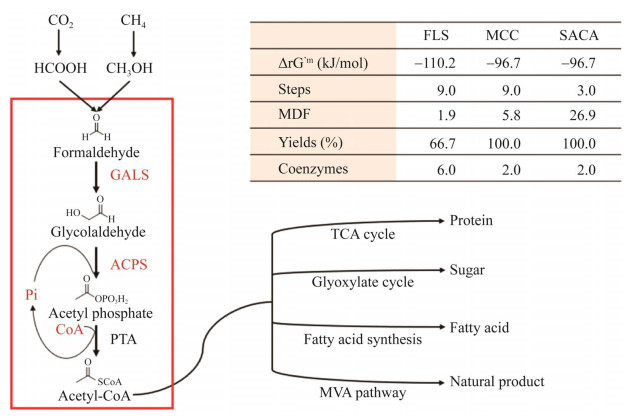

Lu X, Liu Y, Yang Y, et al. Constructing a synthetic pathway for acetyl-coenzyme A from one-carbon through enzyme design. Nat Commun, 2019, 10(1): 1378. DOI:10.1038/s41467-019-09095-z

|

|

| [36] |

Li T, Tang Z, Wei H, et al. Totally atom-economical synthesis of lactic acid from formaldehyde: combined bio-carboligation and chemo-rearrangement without the isolation of intermediates. Green Chem, 2020, 22(20): 6809-6814. DOI:10.1039/D0GC02433C

|

|

| [37] |

Li T, Tan Z, Tang Z, et al. One-pot chemoenzymatic synthesis of glycolic acid from formaldehyde. Green Chem, 2022, 24(13): 5064-5069. DOI:10.1039/D2GC00688J

|

|

| [38] |

Yang J, Zhu Y, Qu G, et al. Biosynthesis of dendroketose from different carbon sources using in vitro and in vivo metabolic engineering strategies. Biotechnol Biofuels, 2018, 11: 290. DOI:10.1186/s13068-018-1293-7

|

|

| [39] |

Bar-Even A, Noor E, Lewis NE, et al. Design and analysis of synthetic carbon fixation pathways. PNAS, 2010, 107(19): 8889-8894. DOI:10.1073/pnas.0907176107

|

|

| [40] |

Orth JD, Thiele I, Palsson BØ. What is flux balance analysis?. Nat Biotech, 2010, 28(3): 245-248. DOI:10.1038/nbt.1614

|

|

| [41] |

Lin Z, Zhang Y, Yuan Q, et al. Metabolic engineering of Escherichia coli for poly(3-hydroxybutyrate) production via threonine bypass. Microb Cell Fact, 2015, 14: 185. DOI:10.1186/s12934-015-0369-3

|

|

| [42] |

Yang X, Yuan Q, Luo H, et al. Systematic design and in vitro validation of novel one-carbon assimilation pathways. Metab Eng, 2019, 56: 142-153. DOI:10.1016/j.ymben.2019.09.001

|

|

| [43] |

Hadadi N, Hafner J, Shajkofci A, et al. ATLAS of biochemistry: a repository of all possible biochemical reactions for synthetic biology and metabolic engineering studies. ACS Synth Biol, 2016, 5(10): 1155-1166. DOI:10.1021/acssynbio.6b00054

|

|

| [44] |

Hafner J, MohammadiPeyhani H, Sveshnikova A, et al. Updated ATLAS of biochemistry with new metabolites and improved enzyme prediction power. ACS Synth Biol, 2020, 9(6): 1479-1482. DOI:10.1021/acssynbio.0c00052

|

|

| [45] |

Bogorad IW, Chen CT, Theisen MK, et al. Building carbon-carbon bonds using a biocatalytic methanol condensation cycle. PNAS, 2014, 111(45): 15928-15933. DOI:10.1073/pnas.1413470111

|

|

| [46] |

Mao Y, Yuan Q, Yang X, et al. Non-natural aldol reactions enable the design and construction of novel one-carbon assimilation pathways in vitro. Front Microbiol, 2021, 12: 677596. DOI:10.3389/fmicb.2021.677596

|

|

| [47] | |

|

| [48] |

Schwander T, Schada von Borzyskowski L, Burgener S, et al. A synthetic pathway for the fixation of carbon dioxide in vitro. Science, 2016, 354(6314): 900-904. DOI:10.1126/science.aah5237

|

|

| [49] |

Yang J, Sun S, Men Y, et al. Transformation of formaldehyde into functional sugars via multi-enzyme stepwise cascade catalysis. Catal Sci Technol, 2017, 7(16): 3459-3463. DOI:10.1039/C7CY01062A

|

|

| [50] |

Li J, Lin L, Sun T, et al. Direct production of commodity chemicals from lignocellulose using Myceliophthora thermophila. Metab Eng, 2020, 61: 416-426. DOI:10.1016/j.ymben.2019.05.007

|

|

| [51] |

Li J, Chen B, Gu S, et al. Coordination of consolidated bioprocessing technology and carbon dioxide fixation to produce malic acid directly from plant biomass in Myceliophthora thermophila. Biotechnol Biofuels, 2021, 14(1): 186. DOI:10.1186/s13068-021-02042-5

|

|

| [52] |

Qi X, Jia X, Wang Y, et al. Development of a rapid startup method of direct electron transfer-dominant methanogenic microbial electrosynthesis. Bioresour Technol, 2022, 358: 127385. DOI:10.1016/j.biortech.2022.127385

|

|

| [53] |

Sadhukhan J, Lloyd JR, Scott K, et al. A critical review of integration analysis of microbial electrosynthesis (MES) systems with waste biorefineries for the production of biofuel and chemical from reuse of CO 2. Renew Sustain Energy Rev, 2016, 56: 116-132. DOI:10.1016/j.rser.2015.11.015

|

|

| [54] |

Wu Z, Wang J, Liu J, et al. Engineering an electroactive Escherichia coli for the microbial electrosynthesis of succinate from glucose and CO(2). Microb Cell Fact, 2019, 18(1): 15. DOI:10.1186/s12934-019-1067-3

|

|

| [55] |

Wu Z, Wang J, Zhang X, et al. Engineering an electroactive Escherichia coli for the microbial electrosynthesis of succinate by increasing the intracellular FAD pool. Biochem Eng J, 2019, 146: 132-142. DOI:10.1016/j.bej.2019.03.015

|

|

| [56] |

Zheng T, Zhang M, Wu L, et al. Upcycling CO 2 into energy-rich long-chain compounds via electrochemical and metabolic engineering. Nat Catal, 2022, 5(5): 388-396. DOI:10.1038/s41929-022-00775-6

|

|

| [57] |

Yuan XJ, Chen WJ, Ma ZX, et al. Rewiring the native methanol assimilation metabolism by incorporating the heterologous ribulose monophosphate cycle into Methylorubrum extorquens. Metab Eng, 2021, 64: 95-110. DOI:10.1016/j.ymben.2021.01.009

|

|

| [58] |

Gao J, Gao N, Zhai X, et al. Recombination machinery engineering for precise genome editing in methylotrophic yeast Ogataea polymorpha. iScience, 2021, 24(3): 102168. DOI:10.1016/j.isci.2021.102168

|

|

| [59] |

Zhang M, Yuan XJ, Zhang C, et al. Bioconversion of methanol into value-added chemicals in native and synthetic methylotrophs. Curr Issues Mol Biol, 2019, 33: 225-236.

|

|

| [60] |

Müller JEN, Meyer F, Litsanov B, et al. Engineering Escherichia coli for methanol conversion. Metab Eng, 2015, 28: 190-201. DOI:10.1016/j.ymben.2014.12.008

|

|

| [61] |

Wang J, Jian X, Xing XH, et al. Empowering a methanol-dependent Escherichia coli via adaptive evolution using a high-throughput microbial microdroplet culture system. Front Bioeng Biotechnol, 2020, 8: 570. DOI:10.3389/fbioe.2020.00570

|

|

| [62] |

Tuyishime P, Wang Y, Fan L, et al. Engineering Corynebacterium glutamicum for methanol-dependent growth and glutamate production. Metab Eng, 2018, 49: 220-231. DOI:10.1016/j.ymben.2018.07.011

|

|

| [63] |

Dai Z, Gu H, Zhang S, et al. Metabolic construction strategies for direct methanol utilization in Saccharomyces cerevisiae. Bioresource Technology, 2017, 245: 1407-1412. DOI:10.1016/j.biortech.2017.05.100

|

|

| [64] |

Chen FY, Jung HW, Tsuei CY, et al. Converting Escherichia coli to a synthetic methylotroph growing solely on methanol. Cell, 2020, 182(4): 933-946.e14. DOI:10.1016/j.cell.2020.07.010

|

|

| [65] |

Fan L, Wang Y, Qian J, et al. Transcriptome analysis reveals the roles of nitrogen metabolism and sedoheptulose bisphosphatase pathway in methanol-dependent growth of Corynebacterium glutamicum. Microb Biotechnol, 2021, 14(4): 1797-1808. DOI:10.1111/1751-7915.13863

|

|

| [66] |

Wang G, Olofsson-Dolk M, Hansson FG, et al. Engineering yeast Yarrowia lipolytica for methanol assimilation. ACS Synth Biol, 2021, 10(12): 3537-3550. DOI:10.1021/acssynbio.1c00464

|

|

2022, Vol. 38

2022, Vol. 38