| [1] |

Geyer R, Jambeck JR, Law KL. Production, use, and fate of all plastics ever made. Sci Adv, 2017, 3(7): e1700782. DOI:10.1126/sciadv.1700782

|

|

| [2] |

Folino A, Karageorgiou A, Calabrò PS, et al. Biodegradation of wasted bioplastics in natural and industrial environments: a review. Sustainability, 2020, 12(15): 6030. DOI:10.3390/su12156030

|

|

| [3] |

Satti SM, Shah AA. Polyester-based biodegradable plastics: an approach towards sustainable development. Lett Appl Microbiol, 2020, 70(6): 413-430. DOI:10.1111/lam.13287

|

|

| [4] | |

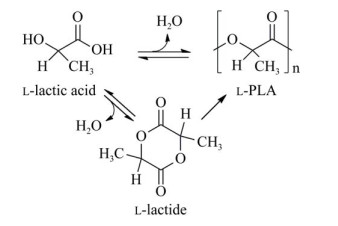

|

| [5] |

Meereboer KW, Misra M, Mohanty AK. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem, 2020, 22(17): 5519-5558. DOI:10.1039/D0GC01647K

|

|

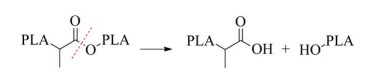

| [6] |

Turco R, Santagata G, Corrado I, et al. In vivo and post-synthesis strategies to enhance the properties of PHB-based materials: a review. Front Bioeng Biotechnol, 2020, 8: 619266.

|

|

| [7] |

Hobbs SR, Parameswaran P, Astmann B, et al. Anaerobic codigestion of food waste and polylactic acid: effect of pretreatment on methane yield and solid reduction. Adv Mater Sci Eng, 2019, 2019: 4715904.

|

|

| [8] |

Nofar M, Sacligil D, Carreau PJ, et al. Poly(lactic acid) blends: processing, properties and applications. Int J Biol Macromol, 2019, 125: 307-360. DOI:10.1016/j.ijbiomac.2018.12.002

|

|

| [9] |

Xu J, Guo BH. Poly(butylene succinate) and its copolymers: research, development and industrialization. Biotechnol J, 2010, 5(11): 1149-1163. DOI:10.1002/biot.201000136

|

|

| [10] |

Puchalski M, Szparaga G, Biela T, et al. Molecular and supramolecular changes in polybutylene succinate (PBS) and polybutylene succinate adipate (PBSA) copolymer during degradation in various environmental conditions. Polymers, 2018, 10(3): 251. DOI:10.3390/polym10030251

|

|

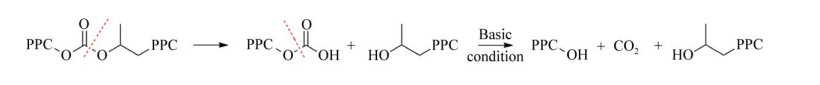

| [11] |

张婷, 张彩丽, 宋鑫宇, 等. PBAT薄膜的制备及应用研究进展. 中国塑料, 2021, 35(7): 115-125. Zhang T, Zhang CL, Song XY, et al. Research progress in preparation and applications of PBAT films. China Plast, 2021, 35(7): 115-125 (in Chinese).

|

|

| [12] |

Mahmoud Salehi AO, Heidari Keshel S, Sefat F, et al. Use of polycaprolactone in corneal tissue engineering: a review. Mater Today Commun, 2021, 27: 102402. DOI:10.1016/j.mtcomm.2021.102402

|

|

| [13] |

刘小文, 潘莉莎, 徐鼐, 等. 聚碳酸亚丙酯共混改性研究进展. 化工进展, 2010, 29(5): 901-908, 975. Liu XW, Pan LS, Xu N, et al. Advances in blending of poly(propylene carbonate). Chem Ind Eng Prog, 2010, 29(5): 901-908, 975 (in Chinese).

|

|

| [14] |

Aslam M, Kalyar MA, Raza ZA. Polyvinyl alcohol: a review of research status and use of polyvinyl alcohol based nanocomposites. Polym Eng Sci, 2018, 58(12): 2119-2132. DOI:10.1002/pen.24855

|

|

| [15] |

张敬勋. 聚碳酸亚丙酯在膜制品中的应用研究[D]. 青岛: 青岛科技大学, 2017.

Zhang JX. Application research of poly(propylene carbonate) for film products[D]. Qingdao: Qingdao University of Science & Technology, 2017 (in Chinese).

|

|

| [16] |

Kasirajan S, Ngouajio M. Polyethylene and biodegradable mulches for agricultural applications: a review. Agron Sustain Dev, 2012, 32(2): 501-529. DOI:10.1007/s13593-011-0068-3

|

|

| [17] |

Haider TP, Völker C, Kramm J, et al. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew Chem Int Ed Engl, 2019, 58(1): 50-62. DOI:10.1002/anie.201805766

|

|

| [18] |

Elsawy MA, Kim KH, Park JW, et al. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew Sustain Energy Rev, 2017, 79: 1346-1352. DOI:10.1016/j.rser.2017.05.143

|

|

| [19] |

Díaz A, Katsarava R, Puiggalí J. Synthesis, properties and applications of biodegradable polymers derived from diols and dicarboxylic acids: from polyesters to poly(ester amide)s. Int J Mol Sci, 2014, 15(5): 7064-7123. DOI:10.3390/ijms15057064

|

|

| [20] | |

|

| [21] |

Al-Itry R, Lamnawar K, Maazouz A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym Degrad Stab, 2012, 97(10): 1898-1914. DOI:10.1016/j.polymdegradstab.2012.06.028

|

|

| [22] |

Ghosh SK, Pal S, Ray S. Study of microbes having potentiality for biodegradation of plastics. Environ Sci Pollut Res, 2013, 20(7): 4339-4355. DOI:10.1007/s11356-013-1706-x

|

|

| [23] |

Numata K, Abe H, Doi Y. Enzymatic processes for biodegradation of poly(hydroxyalkanoate)s crystals. Can J Chem, 2008, 86(6): 471-483. DOI:10.1139/v08-004

|

|

| [24] | |

|

| [25] |

Kumar A, Gross RA, Jendrossek D. Poly(3-hydroxybutyrate)-depolymerase from Pseudomonas lemoignei: catalysis of esterifications in organic media. J Org Chem, 2000, 65(23): 7800-7806. DOI:10.1021/jo000814y

|

|

| [26] |

Reeve MS, McCarthy SP, Downey MJ, et al. Polylactide stereochemistry: effect on enzymic degradability. Macromolecules, 1994, 27(3): 825-831. DOI:10.1021/ma00081a030

|

|

| [27] |

Jaeger KE, Steinbüchel A, Jendrossek D. Substrate specificities of bacterial polyhydroxyalkanoate depolymerases and lipases: bacterial lipases hydrolyze poly( omega-hydroxyalkanoates). Appl Environ Microbiol, 1995, 61(8): 3113-3118. DOI:10.1128/aem.61.8.3113-3118.1995

|

|

| [28] |

Hajighasemi M, Nocek BP, Tchigvintsev A, et al. Biochemical and structural insights into enzymatic depolymerization of polylactic acid and other polyesters by microbial carboxylesterases. Biomacromolecules, 2016, 17(6): 2027-2039. DOI:10.1021/acs.biomac.6b00223

|

|

| [29] | |

|

| [30] |

Kitakuni E, Yoshikawa K, Nakano K, et al. Biodegradation of poly(tetramethylene succinate-co- tetramethylene adipate) and poly(tetramethylene succinate) through water-soluble products. Environ Toxicol Chem, 2001, 20(5): 941-946.

|

|

| [31] |

Hayase N, Yano H, Kudoh E, et al. Isolation and characterization of poly(butylene succinate-co- butylene adipate)-degrading microorganism. J Biosci Bioeng, 2004, 97(2): 131-133. DOI:10.1016/S1389-1723(04)70180-2

|

|

| [32] |

Shah AA, Eguchi T, Mayumi D, et al. Purification and properties of novel aliphatic-aromatic co-polyesters degrading enzymes from newly isolated Roseateles depolymerans strain TB-87. Polym Degrad Stab, 2013, 98(2): 609-618. DOI:10.1016/j.polymdegradstab.2012.11.013

|

|

| [33] |

Artham T, Doble M. Biodegradation of aliphatic and aromatic polycarbonates. Macromol Biosci, 2008, 8(1): 14-24. DOI:10.1002/mabi.200700106

|

|

| [34] |

Murphy CA, Cameron JA, Huang SJ, et al. Fusarium polycaprolactone depolymerase is cutinase. Appl Environ Microbiol, 1996, 62(2): 456-460. DOI:10.1128/aem.62.2.456-460.1996

|

|

| [35] |

Khan I, Ray Dutta J, Ganesan R. Lactobacillus sps. lipase mediated poly(ε-caprolactone) degradation. Int J Biol Macromol, 2017, 95: 126-131. DOI:10.1016/j.ijbiomac.2016.11.040

|

|

| [36] |

Zhou M, Takayanagi M, Yoshida Y, et al. Enzyme-catalyzed degradation of aliphatic polycarbonates prepared from epoxides and carbon dioxide. Polym Bull, 1999, 42(4): 419-424. DOI:10.1007/s002890050484

|

|

| [37] |

Suyama T, Tokiwa Y. Enzymatic degradation of an aliphatic polycarbonate, poly(tetramethylene carbonate). Enzym Microb Technol, 1997, 20(2): 122-126. DOI:10.1016/S0141-0229(96)00084-1

|

|

| [38] |

Kawai F, Hu XP. Biochemistry of microbial polyvinyl alcohol degradation. Appl Microbiol Biotechnol, 2009, 84(2): 227-237. DOI:10.1007/s00253-009-2113-6

|

|

| [39] |

Matsumura S, Tomizawa N, Toki A, et al. Novel poly(vinyl alcohol)-degrading enzyme and the degradation mechanism. Macromolecules, 1999, 32(23): 7753-7761. DOI:10.1021/ma990727b

|

|

| [40] |

Klomklang W, Tani A, Kimbara K, et al. Biochemical and molecular characterization of a periplasmic hydrolase for oxidized polyvinyl alcohol from Sphingomonas sp. strain 113P3. Microbiology (Reading), 2005, 151(pt 4): 1255-1262.

|

|

| [41] |

Uchida H, Shigeno-Akutsu Y, Nomura N, et al. Cloning and sequence analysis of poly(tetramethylene succinate) depolymerase from Acidovorax delafieldii strain BS-3. J Biosci Bioeng, 2002, 93(2): 245-247. DOI:10.1016/S1389-1723(02)80022-6

|

|

| [42] |

Nakajima-Kambe T, Edwinoliver NG, Maeda H, et al. Purification, cloning and expression of an Aspergillus niger lipase for degradation of poly(lactic acid) and poly(ε-caprolactone). Polym Degrad Stab, 2012, 97(2): 139-144. DOI:10.1016/j.polymdegradstab.2011.11.009

|

|

| [43] |

Lee SH, Kim MN. Isolation of bacteria degrading poly(butylene succinate-co-butylene adipate) and their lip A gene. Int Biodeterior Biodegrad, 2010, 64(3): 184-190. DOI:10.1016/j.ibiod.2010.01.002

|

|

| [44] |

Masaki K, Kamini NR, Ikeda H, et al. Cutinase-like enzyme from the yeast Cryptococcus sp. strain S-2 hydrolyzes polylactic acid and other biodegradable plastics. Appl Environ Microbiol, 2005, 71(11): 7548-7550. DOI:10.1128/AEM.71.11.7548-7550.2005

|

|

| [45] |

Akutsu-Shigeno Y, Teeraphatpornchai T, Teamtisong K, et al. Cloning and sequencing of a poly(DL-lactic acid) depolymerase gene from Paenibacillus amylolyticus strain TB-13 and its functional expression in Escherichia coli. Appl Environ Microbiol, 2003, 69(5): 2498-2504. DOI:10.1128/AEM.69.5.2498-2504.2003

|

|

| [46] |

Wang ZY, Wang Y, Guo ZQ, et al. Purification and characterization of poly(L-lactic acid) depolymerase from Pseudomonas sp. strain DS04-T. Polym Eng Sci, 2011, 51(3): 454-459. DOI:10.1002/pen.21857

|

|

| [47] |

Tsuji H, Kidokoro Y, Mochizuki M. Enzymatic degradation of biodegradable polyester composites of poly(L-lactic acid) and poly(ε-caprolactone). Macromol Mater Eng, 2006, 291(10): 1245-1254. DOI:10.1002/mame.200600276

|

|

| [48] |

Satti SM, Abbasi AM, Marsh TL, et al. Statistical optimization of lipase production from Sphingobacterium sp. strain S2 and evaluation of enzymatic depolymerization of poly(lactic acid) at mesophilic temperature. Polym Degrad Stab, 2019, 160: 1-13. DOI:10.1016/j.polymdegradstab.2018.11.030

|

|

| [49] |

Penkhrue W, Khanongnuch C, Masaki K, et al. Isolation and screening of biopolymer-degrading microorganisms from northern Thailand. World J Microbiol Biotechnol, 2015, 31(9): 1431-1442. DOI:10.1007/s11274-015-1895-1

|

|

| [50] |

Sakai K, Kawano H, Iwami A, et al. Isolation of a thermophilic poly-L-lactide degrading bacterium from compost and its enzymatic characterization. J Biosci Bioeng, 2001, 92(3): 298-300. DOI:10.1016/S1389-1723(01)80266-8

|

|

| [51] |

Nawaz A, Hasan F, Shah AA. Degradation of poly(ε-caprolactone) (PCL) by a newly isolated Brevundimonas sp. strain MRL-AN1 from soil. FEMS Microbiol Lett, 2015, 362(1): 1-7.

|

|

| [52] |

Nakajima-Kambe T, Toyoshima K, Saito C, et al. Rapid monomerization of poly(butylene succinate)-co- (butylene adipate) by Leptothrix sp.. J Biosci Bioeng, 2009, 108(6): 513-516. DOI:10.1016/j.jbiosc.2009.05.018

|

|

| [53] |

Shah AA, Nawaz A, Kanwal L, et al. Degradation of poly(ε-caprolactone) by a thermophilic bacterium Ralstonia sp. strain MRL-TL isolated from hot spring. Int Biodeterior Biodegrad, 2015, 98: 35-42. DOI:10.1016/j.ibiod.2014.11.017

|

|

| [54] |

Hu XP, Thumarat U, Zhang X, et al. Diversity of polyester-degrading bacteria in compost and molecular analysis of a thermoactive esterase from Thermobifida alba AHK119. Appl Microbiol Biotechnol, 2010, 87(2): 771-779. DOI:10.1007/s00253-010-2555-x

|

|

| [55] |

Maeda H, Yamagata Y, Abe K, et al. Purification and characterization of a biodegradable plastic-degrading enzyme from Aspergillus oryzae. Appl Microbiol Biotechnol, 2005, 67(6): 778-788. DOI:10.1007/s00253-004-1853-6

|

|

| [56] |

Abou-Zeid DM, Müller RJ, Deckwer WD. Degradation of natural and synthetic polyesters under anaerobic conditions. J Biotechnol, 2001, 86(2): 113-126. DOI:10.1016/S0168-1656(00)00406-5

|

|

| [57] |

Kleeberg I, Welzel K, VandenHeuvel J, et al. Characterization of a new extracellular hydrolase from Thermobifida fusca degrading aliphatic-aromatic copolyesters. Biomacromolecules, 2005, 6(1): 262-270. DOI:10.1021/bm049582t

|

|

| [58] |

Sukkhum S, Tokuyama S, Tamura T, et al. A novel poly(L-lactide) degrading actinomycetes isolated from Thai forest soil, phylogenic relationship and the enzyme characterization. J Gen Appl Microbiol, 2009, 55(6): 459-467. DOI:10.2323/jgam.55.459

|

|

| [59] |

Panyachanakul T, Kitpreechavanich V, Tokuyama S, et al. Poly(DL-lactide)-degrading enzyme production by immobilized Actinomadura keratinilytica strain T16-1 in a 5-L fermenter under various fermentation processes. Electron J Biotechnol, 2017, 30: 71-76. DOI:10.1016/j.ejbt.2017.09.001

|

|

| [60] |

Hanphakphoom S, Maneewong N, Sukkhum S, et al. Characterization of poly(L-lactide)-degrading enzyme produced by thermophilic filamentous bacteria Laceyella sacchari LP175. J Gen Appl Microbiol, 2014, 60(1): 13-22. DOI:10.2323/jgam.60.13

|

|

| [61] |

Jung HW, Yang MK, Su RC. Purification, characterization, and gene cloning of an Aspergillus fumigatus polyhydroxybutyrate depolymerase used for degradation of polyhydroxybutyrate, polyethylene succinate, and polybutylene succinate. Polym Degrad Stab, 2018, 154: 186-194. DOI:10.1016/j.polymdegradstab.2018.06.002

|

|

| [62] |

Volova TG, Boyandin AN, Vasiliev AD, et al. Biodegradation of polyhydroxyalkanoates (PHAs) in tropical coastal waters and identification of PHA-degrading bacteria. Polym Degrad Stab, 2010, 95(12): 2350-2359. DOI:10.1016/j.polymdegradstab.2010.08.023

|

|

| [63] |

Schirmer A, Jendrossek D, Schlegel HG. Degradation of poly(3-hydroxyoctanoic acid)[P(3HO)] by bacteria: purification and properties of a P(3HO) depolymerase from Pseudomonas fluorescens GK13. Appl Environ Microbiol, 1993, 59(4): 1220-1227. DOI:10.1128/aem.59.4.1220-1227.1993

|

|

| [64] |

Mergaert J, Schirmer A, Hauben L, et al. Isolation and identification of poly(3-hydroxyvalerate)-degrading strains of Pseudomonas lemoignei. Int J Syst Bacteriol, 1996, 46(3): 769-773. DOI:10.1099/00207713-46-3-769

|

|

| [65] |

Akbar S, Hasan F, Nadhman A, et al. Production and purification of poly(3-hydroxybutyrate-co-3- hydroxyvalerate) degrading enzyme from Streptomyces sp. AF-111. J Polym Environ, 2013, 21(4): 1109-1116. DOI:10.1007/s10924-013-0600-4

|

|

| [66] |

Tseng M, Hoang KC, Yang MK, et al. Polyester-degrading thermophilic actinomycetes isolated from different environment in Taiwan. Biodegradation, 2007, 18(5): 579-583. DOI:10.1007/s10532-006-9089-z

|

|

| [67] |

Kim MN, Lee AR, Yoon JS, et al. Biodegradation of poly(3-hydroxybutyrate), Sky-Green ® and Mater-Bi ® by fungi isolated from soils. Eur Polym J, 2000, 36(8): 1677-1685. DOI:10.1016/S0014-3057(99)00219-0

|

|

| [68] |

Satti SM, Shah AA, Auras R, et al. Isolation and characterization of bacteria capable of degrading poly(lactic acid) at ambient temperature. Polym Degrad Stab, 2017, 144: 392-400. DOI:10.1016/j.polymdegradstab.2017.08.023

|

|

| [69] |

Satti SM, Shah AA, Marsh TL, et al. Biodegradation of poly(lactic acid) in soil microcosms at ambient temperature: evaluation of natural attenuation, bio-augmentation and bio-stimulation. J Polym Environ, 2018, 26(9): 3848-3857. DOI:10.1007/s10924-018-1264-x

|

|

| [70] |

Kleeberg I, Hetz C, Kroppenstedt RM, et al. Biodegradation of aliphatic-aromatic copolyesters by Thermomonospora fusca and other thermophilic compost isolates. Appl Environ Microbiol, 1998, 64(5): 1731-1735. DOI:10.1128/AEM.64.5.1731-1735.1998

|

|

| [71] |

Witt U, Einig T, Yamamoto M, et al. Biodegradation of aliphatic-aromatic copolyesters: evaluation of the final biodegradability and ecotoxicological impact of degradation intermediates. Chemosphere, 2001, 44(2): 289-299. DOI:10.1016/S0045-6535(00)00162-4

|

|

| [72] | |

|

| [73] |

Chua TK, Tseng M, Yang MK. Degradation of poly(ε-caprolactone) by thermophilic Streptomyces thermoviolaceus subsp. thermoviolaceus 76T-2. AMB Express, 2013, 3(1): 8. DOI:10.1186/2191-0855-3-8

|

|

| [74] |

Urbanek AK, Rymowicz W, Strzelecki MC, et al. Isolation and characterization of Arctic microorganisms decomposing bioplastics. AMB Express, 2017, 7(1): 148. DOI:10.1186/s13568-017-0448-4

|

|

| [75] |

Li F, Yu D, Lin XM, et al. Biodegradation of poly(ε-caprolactone) (PCL) by a new Penicillium oxalicum strain DSYD05-1. World J Microbiol Biotechnol, 2012, 28(10): 2929-2935. DOI:10.1007/s11274-012-1103-5

|

|

| [76] | |

|

| [77] |

Narancic T, Verstichel S, Reddy Chaganti S, et al. Biodegradable plastic blends create new possibilities for end-of-life management of plastics but they are not a panacea for plastic pollution. Environ Sci Technol, 2018, 52(18): 10441-10452. DOI:10.1021/acs.est.8b02963

|

|

| [78] |

Anunciado MB, Hayes DG, Astner AF, et al. Effect of environmental weathering on biodegradation of biodegradable plastic mulch films under ambient soil and composting conditions. J Polym Environ, 2021, 29(9): 2916-2931. DOI:10.1007/s10924-021-02088-4

|

|

| [79] |

Yagi H, Ninomiya F, Funabashi M, et al. Anaerobic biodegradation tests of poly(lactic acid) under mesophilic and thermophilic conditions using a new evaluation system for methane fermentation in anaerobic sludge. Int J Mol Sci, 2009, 10(9): 3824-3835. DOI:10.3390/ijms10093824

|

|

| [80] |

Weng YX, Wang XL, Wang YZ. Biodegradation behavior of PHAs with different chemical structures under controlled composting conditions. Polym Test, 2011, 30(4): 372-380. DOI:10.1016/j.polymertesting.2011.02.001

|

|

| [81] | |

|

| [82] | |

|

| [83] |

Mihai M, Legros N, Alemdar A. Formulation-properties versatility of wood fiber biocomposites based on polylactide and polylactide/thermoplastic starch blends. Polym Eng Sci, 2014, 54(6): 1325-1340. DOI:10.1002/pen.23681

|

|

| [84] | |

|

| [85] |

赵剑豪, 王晓青, 曾军, 等. 聚丁二酸丁二醇酯及聚丁二酸/己二酸-丁二醇酯在微生物作用下的降解行为. 高分子材料科学与工程, 2006, 22(2): 137-140. Zhao JH, Wang XQ, Zeng J, et al. Studies on biodegradation behavior of poly(butylene succinate) and poly(butylene succinate-co-butylene adipate) by microorganisms. Polym Mater Sci Eng, 2006, 22(2): 137-140 (in Chinese). DOI:10.3321/j.issn:1000-7555.2006.02.035

|

|

| [86] |

Anstey A, Muniyasamy S, Reddy MM, et al. Processability and biodegradability evaluation of composites from poly(butylene succinate) (PBS) bioplastic and biofuel co-products from Ontario. J Polym Environ, 2014, 22(2): 209-218. DOI:10.1007/s10924-013-0633-8

|

|

| [87] |

Bagheri AR, Laforsch C, Greiner A, et al. Fate of so-called biodegradable polymers in seawater and freshwater. Glob Challenges, 2017, 1(4): 1700048. DOI:10.1002/gch2.201700048

|

|

| [88] |

王淑芳, 陶剑, 郭天瑛, 等. 脂肪族聚碳酸酯(PPC)与聚乳酸(PLA)共混型生物降解材料的热学性能、力学性能和生物降解性研究. 离子交换与吸附, 2007, 23(1): 1-9. Wang SF, Tao J, Guo TY, et al. Thermal characteristics, mechanical properties and biodegradability of polycarbonates/poly(lactic acid) (PPC/PLA) blends. Ion Exch Adsorpt, 2007, 23(1): 1-9 (in Chinese). DOI:10.3321/j.issn:1001-5493.2007.01.001

|

|

| [89] |

Cho HS, Moon HS, Kim M, et al. Biodegradability and biodegradation rate of poly(caprolactone)-starch blend and poly(butylene succinate) biodegradable polymer under aerobic and anaerobic environment. Waste Manag, 2011, 31(3): 475-480. DOI:10.1016/j.wasman.2010.10.029

|

|

| [90] |

王磊. PBS及其共聚物的丁二酰氯扩链及降解研究[D]. 西安: 陕西科技大学, 2012.

Wang L. Study on degradation and chain extender of PBS and PBS-based polyester[D]. Xi'an: Shaanxi University of Science & Technology, 2012 (in Chinese).

|

|

| [91] |

Massardier-Nageotte V, Pestre C, Cruard-Pradet T, et al. Aerobic and anaerobic biodegradability of polymer films and physico-chemical characterization. Polym Degrad Stab, 2006, 91(3): 620-627. DOI:10.1016/j.polymdegradstab.2005.02.029

|

|

| [92] |

李功松, 陈小光, 汪彩华. 含PVA废水处理工艺探讨. 工业水处理, 2019, 39(10): 20-25, 31. Li GS, Chen XG, Wang CH. Discussion on treatment process of wastewater containing PVA. Ind Water Treat, 2019, 39(10): 20-25, 31 (in Chinese). DOI:10.11894/iwt.2019-0889

|

|

| [93] | |

|

| [94] |

Thellen C, Coyne M, Froio D, et al. A processing, characterization and marine biodegradation study of melt-extruded polyhydroxyalkanoate (PHA) films. J Polym Environ, 2008, 16(1): 1-11. DOI:10.1007/s10924-008-0079-6

|

|

| [95] |

王格侠, 黄丹, 张维, 等. 典型生物降解聚酯在海水中的降解性能. 功能高分子学报, 2020, 33(5): 492-499. Wang GX, Huang D, Zhang W, et al. Degradation performance of typical biodegradable polyesters in seawater. J Funct Polym, 2020, 33(5): 492-499 (in Chinese).

|

|

| [96] |

Tsuji H, Suzuyoshi K. Environmental degradation of biodegradable polyesters 1. Poly(ε-caprolactone), poly[(R)-3-hydroxybutyrate], and poly(L-lactide) films in controlled static seawater. Polym Degrad Stab, 2002, 75(2): 347-355. DOI:10.1016/S0141-3910(01)00240-3

|

|

| [97] |

Benn N, Zitomer D. Pretreatment and anaerobic co-digestion of selected PHB and PLA bioplastics. Front Environ Sci, 2018, 5: 93. DOI:10.3389/fenvs.2017.00093

|

|

| [98] |

Yagi H, Ninomiya F, Funabashi M, et al. Mesophilic anaerobic biodegradation test and analysis of eubacteria and archaea involved in anaerobic biodegradation of four specified biodegradable polyesters. Polym Degrad Stab, 2014, 110: 278-283. DOI:10.1016/j.polymdegradstab.2014.08.031

|

|

| [99] |

Yagi H, Ninomiya F, Funabashi M, et al. Thermophilic anaerobic biodegradation test and analysis of eubacteria involved in anaerobic biodegradation of four specified biodegradable polyesters. Polym Degrad Stab, 2013, 98(6): 1182-1187. DOI:10.1016/j.polymdegradstab.2013.03.010

|

|

| [100] |

Ren YN, Hu J, Yang MR, et al. Biodegradation behavior of poly(lactic acid) (PLA), poly(butylene adipate-co-terephthalate) (PBAT), and their blends under digested sludge conditions. J Polym Environ, 2019, 27(12): 2784-2792. DOI:10.1007/s10924-019-01563-3

|

|

| [101] |

Svoboda P, Dvorackova M, Svobodova D. Influence of biodegradation on crystallization of poly(butylene adipate-co-terephthalate). Polym Adv Technol, 2019, 30(3): 552-562. DOI:10.1002/pat.4491

|

|

| [102] |

Matsumura S, Kurita H, Shimokobe H. Anaerobic biodegradability of polyvinyl alcohol. Biotechnol Lett, 1993, 15(7): 749-754. DOI:10.1007/BF01080150

|

|

| [103] |

Jain R, Tiwari A. Biosynthesis of planet friendly bioplastics using renewable carbon source. J Environ Health Sci Eng, 2015, 13: 11. DOI:10.1186/s40201-015-0165-3

|

|

| [104] |

Boyandin AN, Prudnikova SV, Karpov VA, et al. Microbial degradation of polyhydroxyalkanoates in tropical soils. Int Biodeterior Biodegrad, 2013, 83: 77-84. DOI:10.1016/j.ibiod.2013.04.014

|

|

| [105] |

Wu CS. Preparation, characterization, and biodegradability of renewable resource-based composites from recycled polylactide bioplastic and sisal fibers. J Appl Polym Sci, 2012, 123(1): 347-355. DOI:10.1002/app.34223

|

|

| [106] |

Adhikari D, Mukai M, Kubota K, et al. Degradation of bioplastics in soil and their degradation effects on environmental microorganisms. J Agric Chem Environ, 2016, 5(1): 23-34.

|

|

| [107] |

de Campos A, Marconato JC, Martins-Franchetti SM. The influence of soil and landfill leachate microorganisms in the degradation of PVC/PCL films cast from DMF. Polímeros, 2012, 22(3): 220-227.

|

|

| [108] |

杨晓庭, 吴景贵, 李建明, 等. 半干旱地区土壤中PPC地膜与普通地膜的降解特征研究. 环境科学与技术, 2020, 43(11): 45-53. Yang XT, Wu JG, Li JM, et al. Study on degradation characteristics of PPC plastic film and ordinary plastic film in semi-arid soil. Environ Sci Technol, 2020, 43(11): 45-53 (in Chinese).

|

|

2022, Vol. 38

2022, Vol. 38